Soluciones integrales para que tus instalaciones industriales sean más eficientes, seguras y sostenibles

Soluciones integrales para que tus instalaciones industriales sean más eficientes, seguras y sostenibles

Qué hacemos

Ingeniería

y estudios

Aislamiento

Accesos

Tratamiento

de superficies

Protección pasiva contra incendios

Soluciones

para amianto

KAEFER es un socio que proporciona multiservicios técnicos de ámbito industrial, líder en cada una de sus especialidades para garantizar soluciones de extremo a extremo.

Actualidad

-

KAEFER confirma su asistencia a las 12as Jornadas sobre Seguridad en Operaciones de Mantenimiento en Madrid

KAEFER, líder en soluciones integrales para instalaciones industriales, participa en las 12as Jornadas sobre Seguridad en Operaciones…

-

KAEFER confirma su asistencia a las 12as Jornadas sobre Seguridad en Operaciones de Mantenimiento en Madrid

KAEFER, líder en soluciones integrales para instalaciones industriales, participa en las 12as Jornadas sobre Seguridad en Operaciones…

-

KAEFER amplía su oferta de soluciones

Medio: Empresa XXI | La filial española del grupo de origen alemán se ha adjudicado UPAs del…

-

Entrevista a D. Jesús Carrobles, Director Comercial de Kaefer España y Portugal. «Estamos preparados para abordar las nuevas preocupaciones de la industria naval»

Medio: Rotación | El sector naval se encuentra en un momento de transformación, enfrentando nuevos desafíos en…

-

Nombramiento D. Alfonso Cerezo como Director del área Ensayos No Destructivos (END)

KAEFER REFUERZA EL ÁREA DE ENSAYOS NO DESTRUCTIVOS En su afán por ofrecer soluciones integrales a los…

Para quién

Sectores

Petroquímico / Transformación de metales / Químico / Eléctrico / Naval / Servicios eólicos / Farmaceútico

Servicios para la Industria Naval todo el know-how y la experiencia de KAEFER aplicado al sector naval

Servicios para la Industria Eólica. Especialistas en superficies eólicas y reparación de palas

Proyectos

Últimos proyectos

-

Mega parada de las instalaciones de Dow Norte

Mega parada de las instalaciones de DOW centrada en el cierre de las plantas de Cracker y Octano. KAEFER contribuye con más de 170.000m3 de instalación de andamios, demolición e instalación de 11.000m2 de aislamiento nuevo (lana mineral, poliuretano, foamglass, colchonetas, lámina de aluminio y acero inoxidable).

-

Planta GALP

Trabajos de ignifugado de estructura en fábrica 1 y 2, ejecutados 6.500 m2 en sustitución, llevando a cabo también la preparación de superficie, mediante limpieza manual y 1.500 m2 de reparación. Aplicación de pasta ignifuga en red de cableado (bandejas, cables y sellados), con un total de 41.300 Uds. en conjunto. Para estos trabajos KAEFER…

-

ArcelorMittal

Servicio de mantenimiento de andamios integral para las factorías de Avilés y Veriña. El volumen de andamio montado y desmontado asciende a 185.000m3.

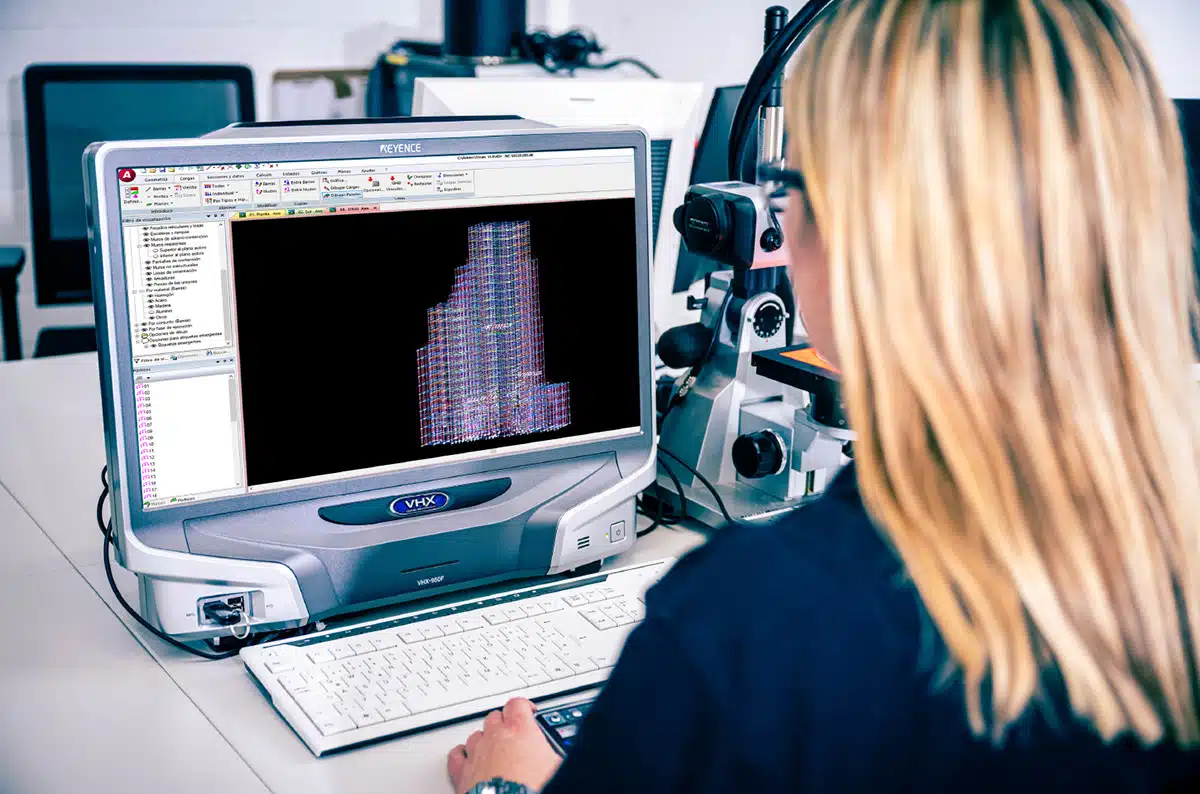

Innovación

Transformación digital

“En KAEFER nos tomamos muy en serio la digitalización, para ser la autoridad en las áreas en las que nos especializamos y brindar excelencia técnica y soporte a nuestros clientes”

El Viaje LEAN

“LEAN nos involucra a todos y hace que los proyectos crezcan, es el resultado de la disciplina, la creatividad y la productividad”

Contacto

Contacta con el equipo comercial

Muchas gracias por contactarnos. Dirigiremos tu consulta al técnico especializado que mejor se ajuste a tus necesidades. Tenemos el compromiso de responder con agilidad y eficiencia.

"*" señala los campos obligatorios